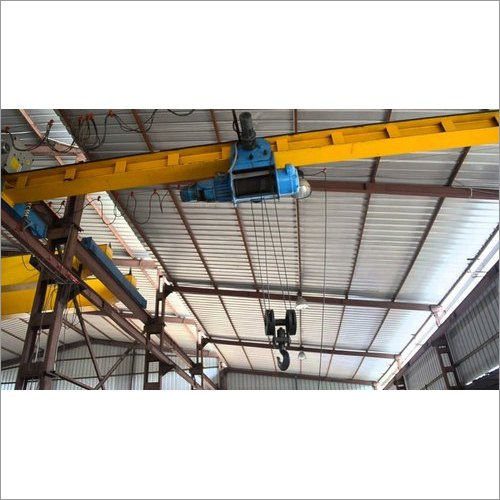

Electric Overhead Travelling Crane

Product Details:

- Color Yellow

- Application Industrial

- Emergency Stop Yes

- Condition New

- Load Capacity 1 ton to 100 ton Long Ton

- Voltage 220 to 415 Volt (v)

- Click to View more

Electric Overhead Travelling Crane Price And Quantity

- 1500000.00 - 8000000.00 INR/Unit

- 1 Unit

Electric Overhead Travelling Crane Product Specifications

- 1 ton to 100 ton Long Ton

- New

- 220 to 415 Volt (v)

- Yellow

- Industrial

- Yes

Electric Overhead Travelling Crane Trade Information

- 1 Unit Per Day

- 1 Days

- All India

Product Description

Electric Overhead Traveling Crane

The Electric Overhead Traveling Crane are designed in accordance with IS: 807, IS: 3177. Suitable factor of safety are considered as per duty class I, II, III & IV the crane bridge is designed either from Rolled Steel I Section or fabricated with Plates. End carriage are fabricated from Rolled steel I - section or with plates & provided with L- type(Housing) double flanged or Pad plate type wheels of suitable diameter of wheels with spherical roller bearings.

Capacity : Up to 15 Tons

Span : Up to 25 Mtr.

Lift of height : 6 Mtrs & Above

Hoist Unit:-

Varun Hoist unit are designed in accordance with is 3938 having modular construction suitable to run on I section or Box girder. Hoist & cross travel motor, gear box, and Brake are easily accessible for maintenance.

Long Travel Drive:-

Either twin or centrally driven provided depending on span length and capacity of the crane .

Control Equipment:-

Operated through push button station or Cabin operated with master control or remote control.

Control Panel:-

Each motor is operated by push button through contactors having Control voltage of 24V/110V for safety of operator. Protective panel consisting of overload relay, MCB / Fuses housed in control panel box. Electrical supply shall be AC 3ph, 400/440V, 50HZ

Test Load:-

The crane shall be tested at 25% overload of safe working load, Test load are to be arranged by purchaser at site.

Special Features:-

Designs conform to IS-807, IS-3177.Optimum Design ensuring minimum Dead Weight, Wheel Loads, Head Rooms and Clearances.Forged Runner Wheels on Spherical Roller Bearings, resulting in long trouble free service.Hobbed and Run-In Heat Treated Gears form High Carbon & Alloy Steels for long trouble free service.Standardized Unit Sub-Assemblies used for complete range, ensuring possibility of spares supply form stocks.Quick Deliveries and Prompt after Sales Service

Designed:-

Amply Proportioned Main Girder and End Carriages form Rolled Sections, with cover Plates or Fabricated Girder. Main Girder further stiffened with Auxiliary Girder and End-Tied to End Carriages, restricting the Equivalent Length & Compressive Stresses.Well Proportioned Rotating Axle type Runner Wheels on US-SGEOT Cranes. Rope Drum fabricated form IS-226, stress relived & long seams 100% Radio graphed.

Bridge Drive:-

Single/Twin Drive with Squirrel Cage/Slip Ring Induction Motors through Totally Enclosed, oil Immersed, Helical Gearboxes in case of SGEOT Cranes.Twin Drive through Unique Conical Rotor type Squirrel Cage Induction Geared Motors with built-in fail safe brakes in case of US-SGEOT Cranes.

Motors:-

Unique Conical Rotor Type Squirrel Cage Induction Hosting Motors with built-in Brakes for Hosting and Cross Travel, Foot Mounted, IEC Frame Size, Crane Duty Motors for Long Travel. Insulation class for all motors B/F.

Brakes:-

Built-in Electro Mechanical Brakes for Hosting and Cross Travel Motions.Electro Hydraulic Thrusters for Long Travel in case of SGEOT Cranes and Built ?in Electro Mechanical Brakes in case of US-SGEOT Cranes.

Crane Control:-

From Floor through Pendant Push Buttons, operating at 100/24V.Electrical Switch Gears mounted inside a dust proof Control Panel, with suitable access for maintenance.

Power Supply System:-

To Hoist & Cross Travel through Trailing Cables. To crane through Trailing Cable / M. S. Angle iron Conductors / bare Copper Conductors to customer choice.